Roadmap

HJT cells combine the benefits of crystalline silicon and thin-film technologies. With outstanding light absorption and passivation, HJT outperforms TOPCon in both efficiency and performance.

As one of the leading solar cell technologies, it maximizes conversion efficiency and power output, representing the future direction of next-generation cell technology.

2021

24.5%

475 W

M6-144

2022

25.1%

715 W

G12-132

2023

25.5%

735 W

G12-132

2024

26.0%-26.5%

760 W

G12-132

2026

28.0%

800 W

HJT+ Perovskite

Roadmap of HJT Solar Wafer (SEW)

Half-cut Ingot

Novel Gettering

Tungsten Wire Cut

Granular Silicon

Roadmapof HJT solar cell

HJT + Perovskite Tandem

Tandem

0BB

Larger & Thinner Wafer in Mass Production (G12/G12R-half, 90 μm)

Low Ag Consumption

TCO Composite Film

Passivation

Nano-C/μC-Si

α-Si Composite Film for Low Damage

Roadmap of HJT solar module

Light Management

Flexible/Curved Encapsulation

High-reliability Encapsulation

High-precision SMBB

High-bifaciality Module

0BB Soldering

Corrosion-resistant Module for Offshore PV

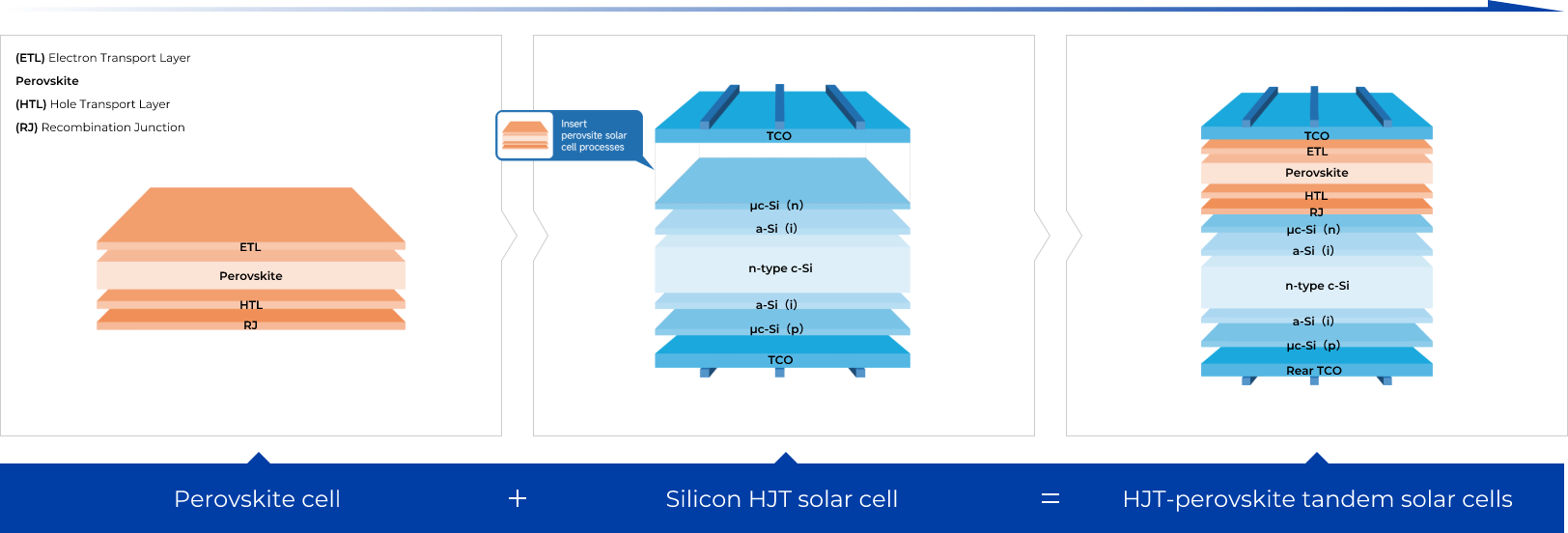

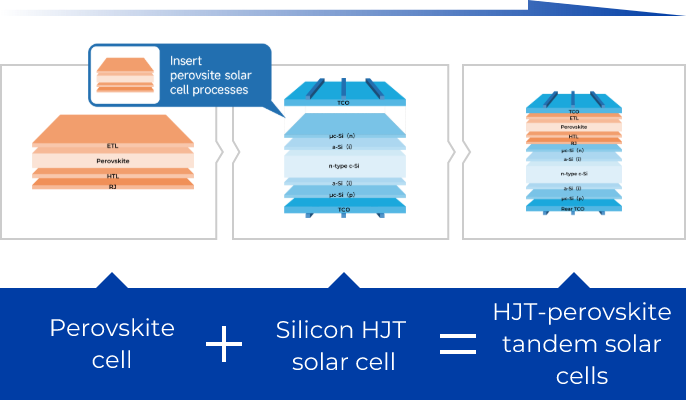

HJT-perovskite tandem solar cells

01

By capitalizing on the inherent advantages of thin-film process of HJT solar cells, the integration of a wide-bandgap perovskite cell enables the formation of a high open-circuit voltage, dual-junction tandem structure.

02

The tandem cell can be

implemented within existing

crystalline silicon (c-Si) production

lines by incorporating perovskite

processing equipment, minimizing

additional infrastructure

investment.

implemented within existing

crystalline silicon (c-Si) production

lines by incorporating perovskite

processing equipment, minimizing

additional infrastructure

investment.

03

HJT-perovskite technology can be

seamlessly integrated with HJT

production lines, optimizing cost

efficiency and streamlining

industrial scalability.

seamlessly integrated with HJT

production lines, optimizing cost

efficiency and streamlining

industrial scalability.

HJT, The Next-generation Mainstream of Solar Technology

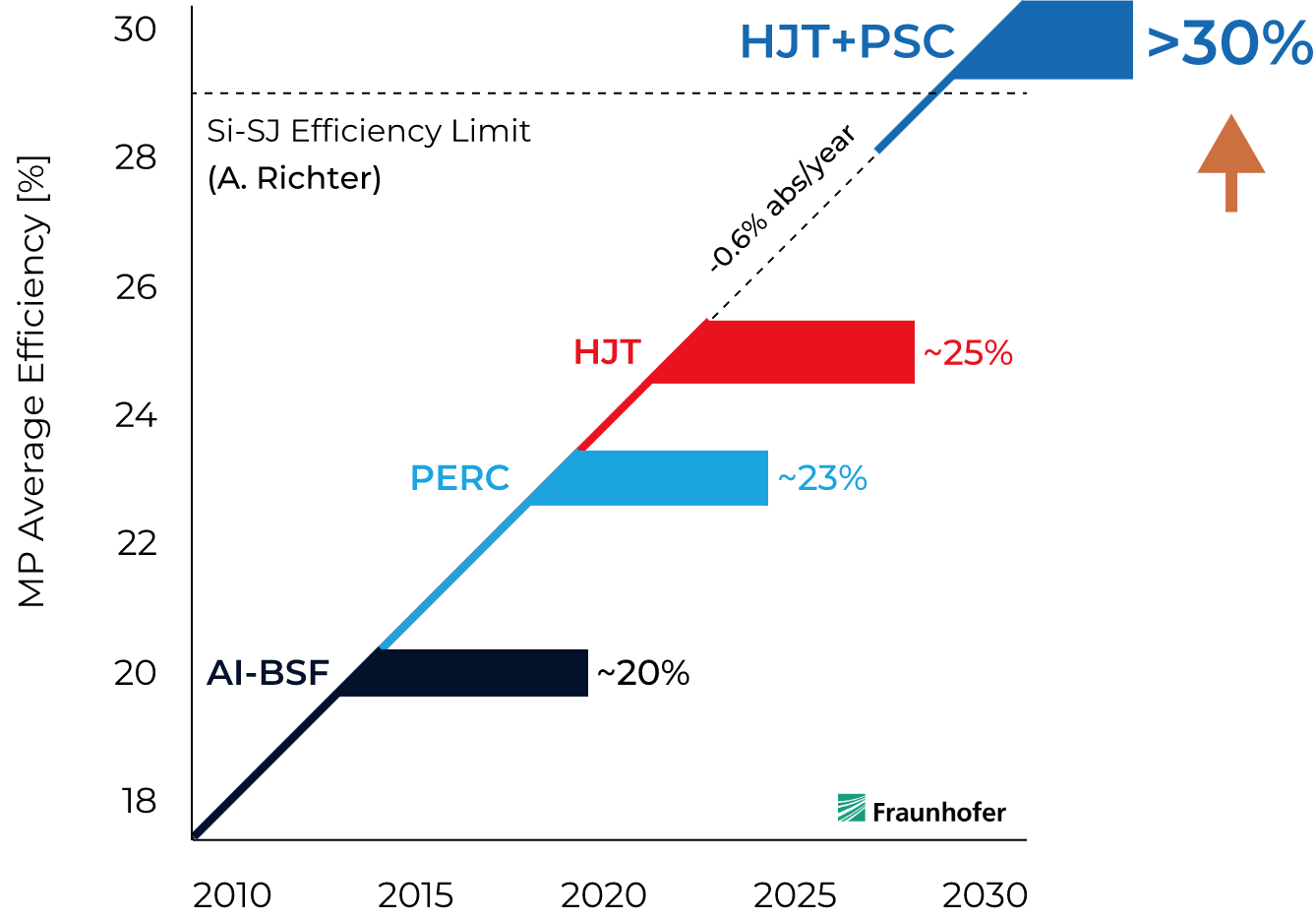

The efficiency of single-junction crystalline silicon (c-Si) solar cells is approaching its theoretical limit, necessitating the exploration of next-generation technological breakthroughs.

- By integrating perovskite with HJT technology in a tandem structure, the spectral utilization efficiency can be significantly enhanced.

- The theoretical efficiency limit of perovskite-silicon tandem solar cells exceeds 43%, far surpassing that of single-junction silicon cells.

- The tandem structure effectively reduces out-of-band absorption and thermal relaxation losses in crystalline silicon cells, further improving overall energy conversion efficien.

HJT

HJT technology represents the future mainstream platform in the crystalline silicon (c-Si) solar industry.

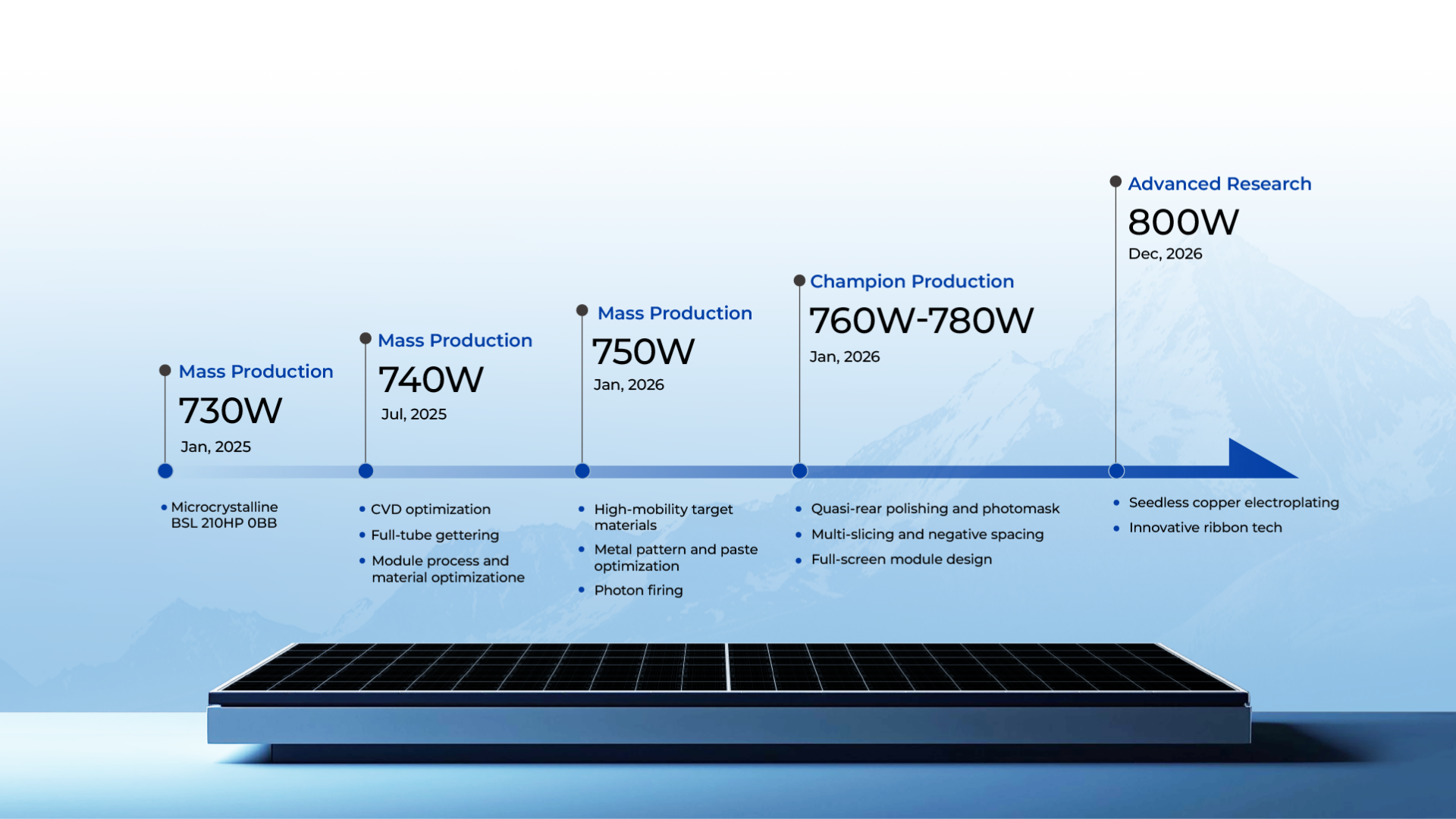

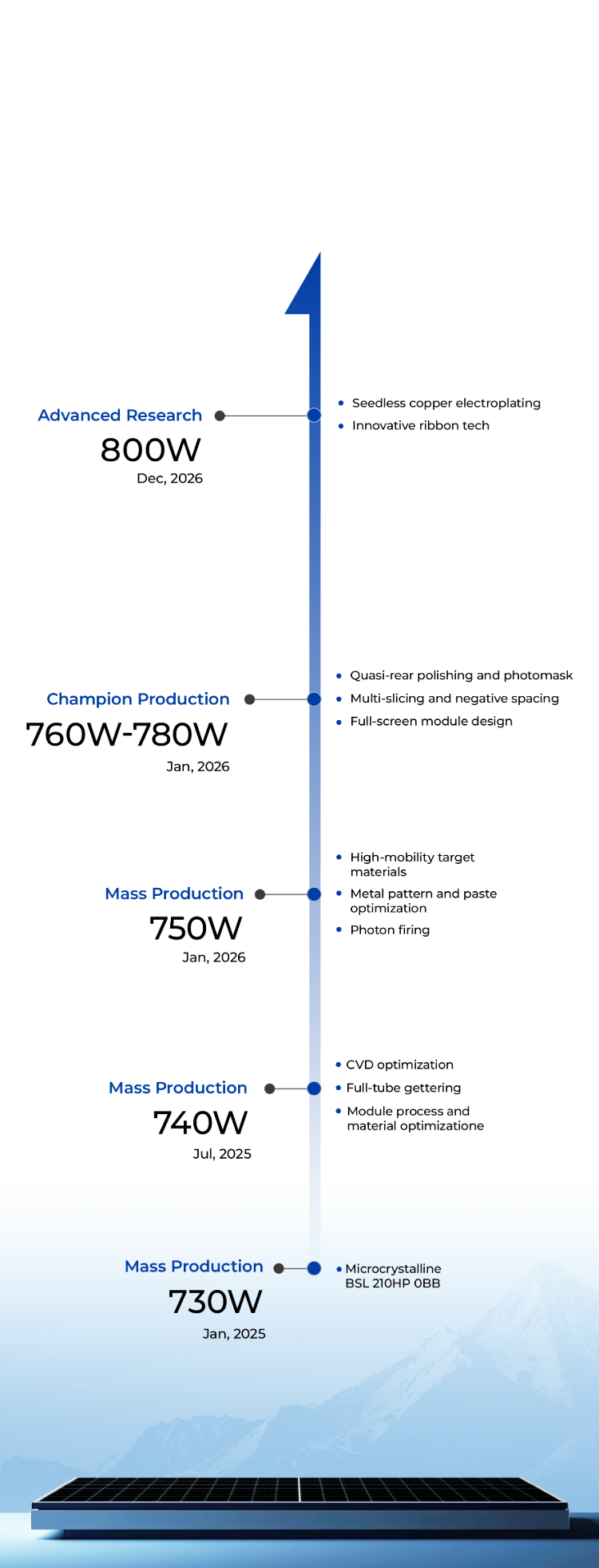

30%+

The HJT-perovskite tandem structure is a promising technological pathway capable of achieving 30%+ cell efficiency in mass production.

800W+

By 2026, the power output of HJT-perovskite tandem modules is expected to exceed 800W, marking a significant breakthrough in photovoltaic performance and commercialization.

760W+ HJT Leadership Initiative

Roadmapof HJT solar cell

Roadmap of HJT solar module

Roadmap of HJT Solar Wafer (SEW)

HJT + Perovskite Tandem

Tandem

0BB

Larger & Thinner Wafer in Mass Production (G12/G12R-half, 90 μm)

Low Ag Consumption

TCO Composite Film

Passivation

Nano-C/μC-Si

α-Si Composite Film for Low Damage

Light Management

Flexible/Curved Encapsulation

High-reliability Encapsulation

High-precision SMBB

High-bifaciality Module

0BB Soldering

Corrosion-resistant Module for Offshore PV

Half-cut Ingot

Novel Gettering

Tungsten Wire Cut

Granular Silicon

newsroom

exhibitions